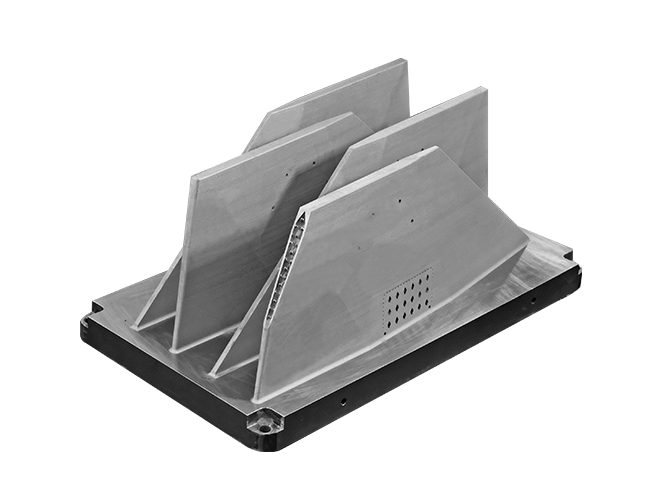

Farsoon FS721M

Large-frame Metal System boosts optimal productivity and great ROI

Farsoon FS721M Brochure

Download

Details

| Brand | |

|---|---|

| Build Volume | 28.3×16.5×16.5 in / 720x420x420 mm |

| Net Weight | Approx. 5000 kg (11023.1 lb) |

| External Dimensions (L×W×H) | 6610mm×1830mm×2500mm (260.2×72.0×98.4 in) |

| Layer thickness | |

| Scanning Speed | Max. 10.0 m/s ( 32.8 ft/s ) |

| Laser Type | Dual Lasers, 2×500W (FS721M-2), Eight Lasers, 8×1000W (FS721M-8), Quad Lasers, 4×500W (FS721M-4) |

| Scanner | F theta lenses or dynamic focusing system (FS721M-2)(FS721M-4), F theta lenses (FS721M-8) |

| Inert Gas Protection | Argon/Nitrogen |

| Average Inert Gas Consumption in Process | 6-8 L / min |

| Operating system | 64 bit Windows 10 |

| Software | BuildStar, MakeStar® |

| Data File Format | STL |

| Key Software Features | Open machine key parameters, real-time build parameter modification, three-dimensional |

| Power Supply | EUR/China: 400V±10%, 3~/N/PE, 50Hz, 40A US: transformer sold with machine |

| Operating Ambient Temperature | 22-28°C (71.6-82.4℉) |

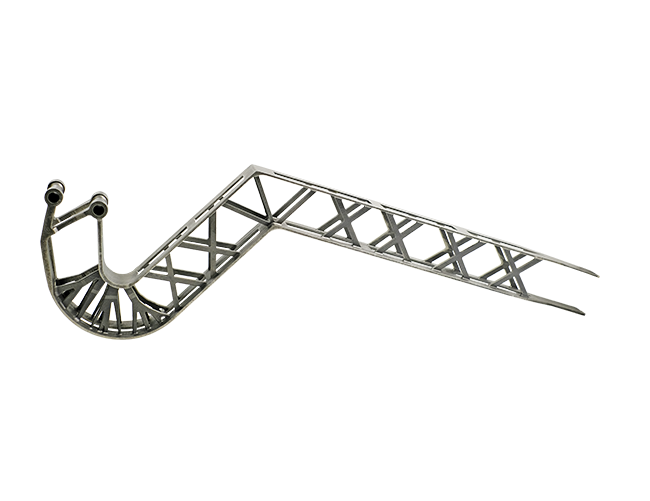

| Materials | 316L, AlSi10Mg, HX, IN718, Maraging Steel Grade 300, TA15, Ti6Al4V |

| 3D printers | DLMS |

| Printing material | Metal |