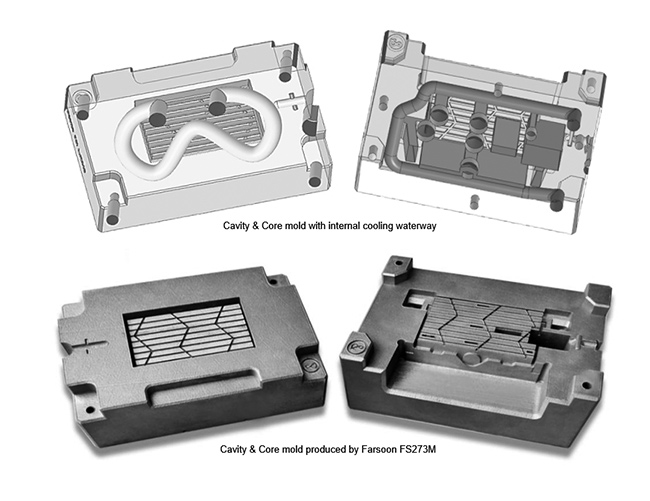

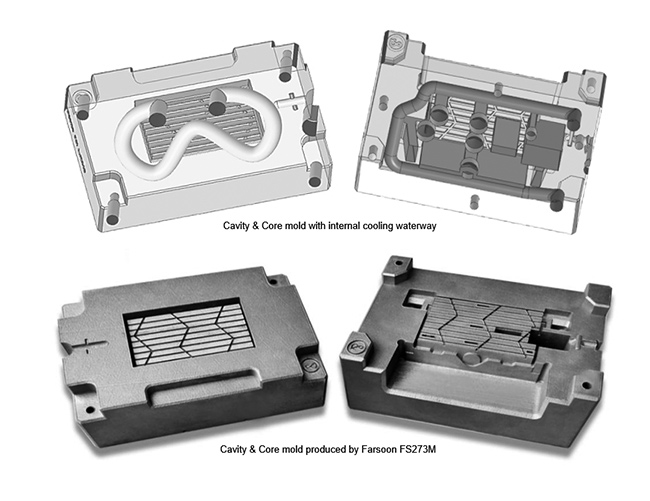

Machine: FS273M-2 Material: 420 Stainless Steel Build time: 20 hours

This set of cavity & core mold is the key components in the whole injection molding system to produce router shell. Because of its complex structure with internal cooling channels, the traditional production takes more than 2 weeks including machining, assembly and post processing. Now with Farsoon’s 273M System, the engineers are able to combine multiple parts into a single part with good material melting uniformity. It also achieved a reduced lead time of only 48 hours and improved surface resolution without the need for further post-processing.

Machine: FS273M-2 Material: Tantalum

Thanks to Farsoon’s additive technology, organic porous structure design can be applied to the tantalum tibia implant, featuring superior biocompatibility, osteoinductive and bacteriostatic capability compared with traditional implants. The additively designed and manufactured porous tantalum structure has similar elastic modulus with human bone, making it easier and faster for bone tissue integration after the surgery.

Machine: FS273M-2 Material: Titanium Size: 204 x 134 x 50 (H) mm Build Time: 20 Hours

This automotive suspension upright innovative design allows for enhanced structural integration thanks to Farsoon’s additive technology. Compared to traditional methods, the optimized design features light-weighting of 40% compared to the traditionally machined parts; Designed and manufactured as an end-use part, the suspension upright can meet the required mechanical performance, and showcasing an improved stability of the automotive suspension system.

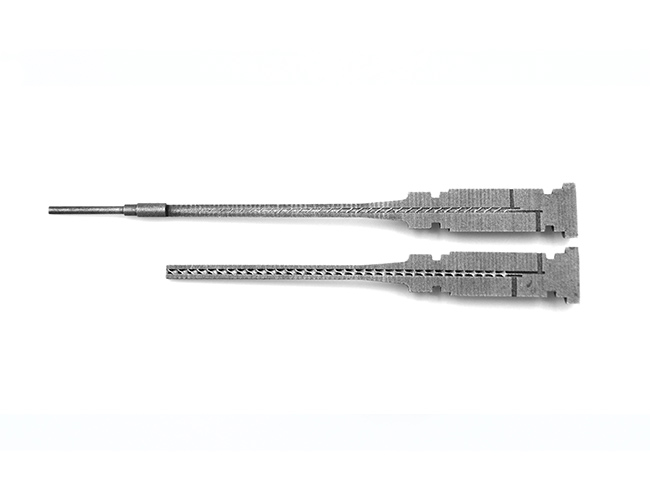

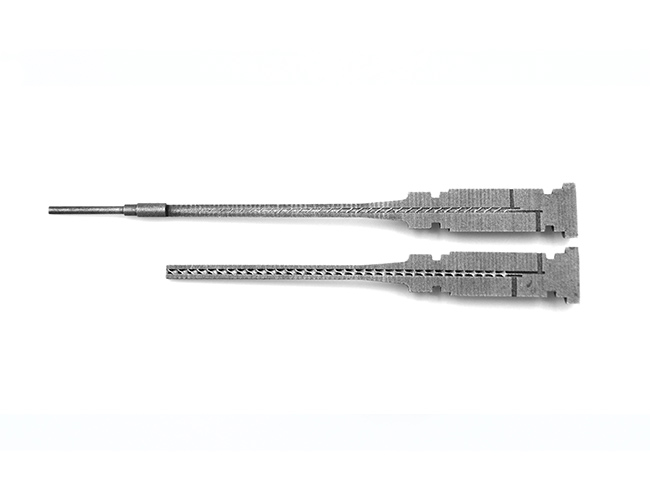

Machine: FS273M-2 Material: Stainless Steel 316L Reduce operation temperature by: 5℃ Increased waterflow speed by: 43%

Featured with a narrow shape and complex internal cooling channels, the traditional manufacturing process of this pen mold insert is extremely challenging – often result in unevenness of the wall thickness, demolition and leakage. Thanks to Farsoon metal 3D printing, the engineers are able to create a double spiral structure conformal cooling channel. It increases the surface of the waterway to reduce each cycle time of cooling operation by 30%; and boosting an improved cooling effects and optimal final product quality.